NedZink NOVA

Quality

NedZink produces titanium zinc according to EN 988, an alloy based on electrolytically cleaned zinc with a purity of min. 99.995 % Zn (Z1 according to EN 1179) with small additions of the alloy elements copper, titanium and aluminium.

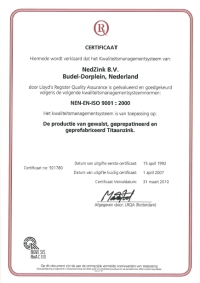

The chemical composition, the mechanical and physical properties and measurement tolerances are determined in the KOMO product certificate and the product certificate from Lloyd’s Register, Industrial Quality Scheme for Product Certification by Surveillance of Quality Systems (approval No. QIS 122).

Compliance with the set material properties is checked at regular intervals (several times a year) by an independent and neutral control body, Lloyd’s Register.

Chemical composition

Product requirements |

NedZink titanium zinc |

Product requirements

according to DIN EN 988 |

Zinc |

Zn 99.995% |

Zn 99.995% |

Copper |

Cu 0.08 - 0.17% |

Cu 0.08 - 1.0% |

Titanium |

Ti 0.07 - 0.12% |

Ti 0.06 - 0.2% |

Aluminium |

Al < 0.015% |

Al < 0.015% |

Size tolerances for standard products

Product requirements |

NedZink titanium zinc |

Product requirements

according to DIN EN 988 |

Sheet and coil thickness |

± 0.025 mm |

± 0.03 mm |

Sheet and coil width |

+ 2/-0 mm |

+ 2/-0 mm |

Sheet length |

+ 2/-0 mm |

+ 10/-0 mm |

Mechanical & technological properties

Product requirements |

NedZink titanium zinc |

Product requirements

according to DIN EN 988 |

Yield strength elasticity (Rp 0.2) |

min. 110N/mm2 |

min. 110N/mm2 |

Tensile strength (Rm) |

min. 150 N/mm2 |

min. 150 N/mm2 |

Elongation (A50) |

min 40% |

min 40% |

Vickers hardness (HV 3) |

min. 40 |

- |

Folding test |

1. no fractures on the fold

2. no cracks

3. relative tensile strength D > 0,7x

original tensile strength |

no fractures on the fold |

Permanent stretch in creep test |

max. 0,1% |

max. 0.1% |

Edgewise bow |

max. 1.5mm/m |

max. 1.5mm/m |

Flatness-corrugation |

max. 2mm |

max. 2mm |

Independent product control |

several times a year |

- |

Guarantee |

10 years |

- |

Quality management system |

DIN EN ISO 9001-2008 |

|

Physical properties

Density |

7.2 g/cm3 |

Melting point |

420 °C |

Recrystallisation temperature |

> 300 °C |

Linear expansion coefficient |

0.022 mm/(mK) |

The materials are provided with a continuous stamp with a mark according to the provisions of NEN-EN 988, mentioning the producer, the product description in German, Dutch, English and French, the EN 988 standard, the nominal thickness, the batch number, the year of production and the logos of the control bodies Lloyd’s Register and KOMO (K7054).

This product certificate and the ISO 9001:2008 certificate for the quality management system at NedZink assure a constant and uniform high quality, meeting our own standards and far exceeding NEN-EN 988.

NedZink titanium zinc is characterised by high durability and excellent deformation properties, and is extremely weather-resistant, durable and maintenance-free.